Which source is more cost-effective—and how to avoid hidden expenses.

Introduction:

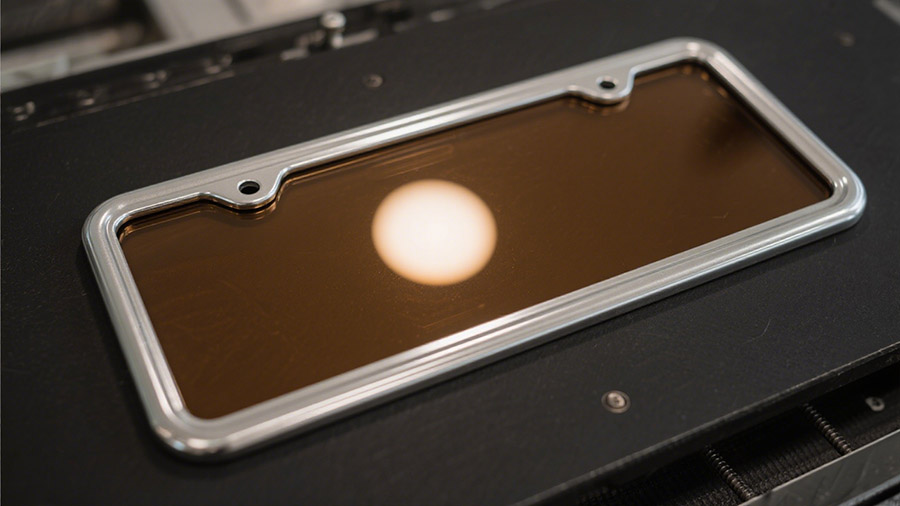

When choosing a license plate frame supplier, U.S. brands and gift product companies are often caught between domestic production and overseas OEM. As a China-based manufacturer specializing in metal and plastic license plate frames, we’ve worked closely with American buyers to navigate these tradeoffs.

In 2025, production cost differences between the U.S. and China remain significant—but not always as simple as “China is cheaper.” Let’s break down the real numbers, cost structures, and manufacturing implications so you can make informed sourcing decisions.

1. Labor Costs: A Core Cost Driver

- U.S.: Factory labor averages $18–$30/hour, depending on state and unionization. Even for basic injection molding or stamping operations, labor remains a substantial portion of COGS.

- China: Labor cost in our facility region (Guangdong) averages $3–$5/hour, with higher efficiency per line due to specialization and automation.

- Takeaway: For labor-intensive processes like manual polishing, pad printing, or kit assembly, Chinese factories hold a clear cost advantage.

2. Tooling & Mold Fees

- U.S.: Aluminum injection molds or stamping dies can range from $8,000 to $20,000, especially with longer timelines and stricter OSHA/safety protocols.

- China: We offer full mold fabrication in-house, with typical mold costs for license plate frames starting from $1,800–$4,000, depending on complexity and plating finish.

- OEM Insight: Our clients often amortize mold fees over 1–2 years of orders.

3. Material Cost: Nearly Equal, But Volume Wins

- Steel, aluminum, ABS, or PP resins are globally traded. Prices per ton/kg fluctuate with oil, shipping, and commodity markets.

- Chinese suppliers often get better rates by pooling bulk materials for multiple clients—especially in automotive accessories zones.

4. Finishing & Decoration

- U.S.: Chrome plating, powder coating, or UV printing tends to be more costly due to EPA compliance and limited plating capacity.

- China: We offer in-house finishing options including:

- Mirror chrome plating

- Soft-touch paint

- Pad printing + UV clear coat

- Hot stamping

- OEM Insight: For holiday frames or limited editions, decorative finishing in China offers faster turnaround and lower MOQ.

5. Packaging & Kitting Services

- U.S. suppliers often outsource kitting (e.g. adding screws, header cards, blister packs), which raises per-unit costs.

- We provide integrated kitting with polybagging, sticker labeling, and barcoding—all in one workflow.

- Value Add: Some clients save 20–30% by moving packaging assembly offshore.

6. Shipping & Lead Time Considerations

- Ocean Freight: While international freight remains a variable, our clients often balance lower unit costs with slightly longer lead times.

- In 2025, we recommend buffering 30–45 days for full production + transit. Air shipping is also available for urgent reorders.

- DTC Tip: We support FBA preparation (e.g. inner cartons, SKU labeling) for U.S. Amazon brands.

7. Compliance & Risk Management

- U.S. suppliers are local, but not always more compliant. In China, we help clients meet RoHS, REACH, and California Prop 65 through pre-tested materials and plating chemistry reports.

- Tip for buyers: Request test reports from both U.S. and overseas factories to ensure your product won’t face customs or listing issues.

Final Comparison Table: U.S. vs. China (2025 Snapshot)

| Cost Component | U.S. Production | China OEM (Our Facility) |

| Labor | $18–$30/hr | $3–$5/hr |

| Mold/Tooling Fee | $8,000–$20,000 | $1,800–$4,000 |

| Finishing & Decoration | Limited / Costly | Full-service, lower cost |

| MOQ | Often higher (≥5,000) | Flexible (starting at 1,000) |

| Packaging & Kitting | Outsourced | In-house |

| Freight & Lead Time | Faster (domestic) | Lower unit cost, 30–45 days |

| Compliance Capability | High | RoHS/REACH ready |

Conclusion:

Sourcing license plate frames from China in 2025 still offers a significant cost advantage—especially for customized designs, plated finishes, and gift packaging. But choosing the right supplier is critical.

We’re happy to provide transparent pricing, free samples, and mold-sharing options to help you assess feasibility before committing.

📩 Contact us

Thinking about shifting production or launching a new frame? Let’s talk about timelines, costs, and what’s possible in today’s global market.