Introduction: Premium Frames, Premium Expectations

In 2025, the U.S. and European license plate frame markets are moving beyond basic plastic and stainless steel. Premium buyers — from automotive enthusiasts to boutique car accessory brands — are looking for materials that communicate status, performance, and craftsmanship.

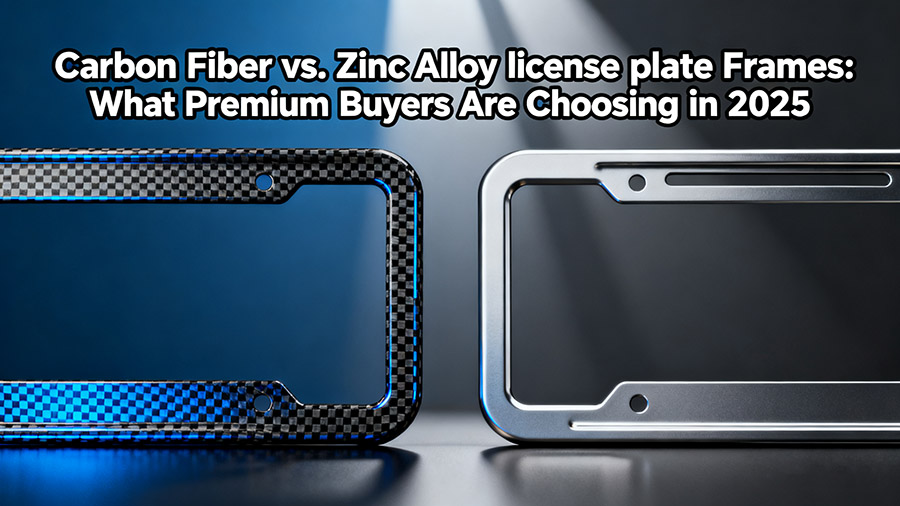

Two materials are leading this segment: carbon fiber and zinc alloy. While both command higher prices, their properties, production methods, and brand associations differ greatly.

From the perspective of a Chinese OEM manufacturer working with international brands, understanding the engineering and manufacturing implications behind these materials is essential for achieving consistent quality, scalability, and profitability.

1. Material Overview: What Defines “Premium” in Frames

- Carbon Fiber: Known for its ultra-lightweight and strength-to-weight ratio. It’s the same material used in aerospace and supercar parts. A carbon fiber frame feels sleek, modern, and performance-driven.

- Zinc Alloy: Heavier, denser, and ideal for chrome or matte metallic finishes. Zinc frames appeal to buyers who value durability, solid texture, and detailed surface treatment.

In short:

Carbon fiber says “innovation and sportiness.”

Zinc alloy says “luxury and craftsmanship.”

2. Weight and Durability: A Matter of Feel

- Carbon Fiber: Typically weighs less than half of zinc alloy. This makes it easier to install and less likely to stress mounting points. However, it requires a protective coating to prevent UV discoloration and resin cracks.

- Zinc Alloy: Offers a heavy, solid hand-feel — which many customers associate with quality. But that weight can be a drawback in some markets (like Europe), where fuel efficiency and lightweighting trends are influencing accessory design.

From an OEM production standpoint, this affects shipping cost, mold design, and structural reinforcement needs.

3. Surface Finish Possibilities

Carbon Fiber Frames:

- Glossy or matte resin finish

- Visible carbon weave pattern

- UV-resistant clear coat

- Optional printing or laser etching for logos

Zinc Alloy Frames:

- Chrome plating, powder coating, or painting

- Antique, brushed, or satin metal textures

- 3D relief logos and intricate engravings

👉 For brand differentiation, zinc alloy allows more decorative depth, while carbon fiber’s aesthetic relies on its natural weave beauty.

4. Production Technology and Tooling

From a manufacturing perspective:

| Feature | Carbon Fiber | Zinc Alloy |

| Process | Hand lay-up, compression molding, or vacuum forming | Die casting and CNC finishing |

| Tooling Cost | Moderate (depends on mold size) | Higher (precision die casting molds) |

| Cycle Time | Slower (manual layers, curing) | Faster (mass casting) |

| Scalability | Better for limited editions | Better for high-volume OEM runs |

For Chinese OEMs, zinc alloy frames are often more suitable for large retail orders or chain-store packaging programs, while carbon fiber fits niche or performance-oriented brands.

5. Branding and Market Positioning

| Buyer Segment | Preferred Material | Key Value Perception |

| Sports / Performance Brands | Carbon Fiber | Lightweight, high-tech, modern |

| Luxury & Gift Brands | Zinc Alloy | Premium weight, metallic shine |

| OEM Car Accessories | Mixed | Depends on cost vs. image priorities |

In 2025, carbon fiber is becoming popular among Tesla, BMW, and Corvette owners — a sign of performance aesthetics. Meanwhile, zinc alloy remains the go-to for brands that want shine, texture, and gift-like appeal.

6. Cost Considerations and Supply Chain Impact

| Factor | Carbon Fiber | Zinc Alloy |

| Material Cost | High | Moderate |

| MOQ (Minimum Order Quantity) | Lower feasible for handmade runs | Higher due to die casting |

| Defect Risk | Color variation, weave alignment | Surface blistering, plating issues |

| Shipping Weight | Light | Heavy |

An experienced OEM can help brands balance these trade-offs. For example, a brand might choose zinc alloy for its main retail SKU and carbon fiber for a “special edition” drop to test premium buyer response.

7. Environmental and Compliance Factors

As sustainability regulations tighten, especially in the EU, both materials face different scrutiny:

- Carbon Fiber: Non-recyclable in most cases, but low emissions in usage stage due to light weight.

- Zinc Alloy: Recyclable and RoHS-compliant, but plating and coating processes must meet environmental standards.

OEM factories with in-house surface treatment lines must ensure REACH, RoHS, and EPA-compliant operations to meet brand audit standards.

8. OEM Recommendations: Choosing the Right Material

For international buyers, here’s how to decide:

- Match Your Brand Image:

- Performance-driven? → Carbon Fiber

- Gift, luxury, or corporate? → Zinc Alloy

- Check Your Retail Channel:

- Online (Amazon, Shopify): Lightweight carbon frames lower shipping cost.

- In-store (AutoZone, Walmart): Zinc frames feel heavier and look more “premium” in packaging.

- Prototype Early:

Always request both 3D CAD (STEP/STP) and 2D logo layout (AI, PDF) before production. A professional OEM partner can validate tolerances and surface finish compatibility. - Think Lifecycle:

Some brands alternate: one zinc alloy line for year-round retail, and one carbon fiber line for limited summer or motorsport editions.

Conclusion: Two Materials, Two Messages

Carbon fiber and zinc alloy frames both define the high end of the 2025 market — but they tell different stories.

- Carbon Fiber: The language of innovation, performance, and modern aesthetics.

- Zinc Alloy: The language of tradition, weight, and timeless luxury.

As a Chinese OEM manufacturer serving U.S. and European brands, our role is to translate your design vision into scalable, compliant, and market-ready products.

Whether your next launch targets car enthusiasts or boutique luxury buyers, choosing the right material — and the right manufacturing partner — will make all the difference.

Call to Action:

Ready to develop your premium frame line?

Contact us to explore material samples, production options, and market-tested finishes for your next carbon fiber or zinc alloy collection.