From concept to delivery—what every brand should know before working with a factory partner.

Introduction: Why is launching a custom license plate frame so hard?

You’ve got the idea. You know your customers want a sleek, branded license plate frame—maybe for a retail line, a holiday promotion, or even a car club. But the road from idea to actual product can feel confusing:

- How do I find a factory that understands my needs?

- Do I need a mold? How much does it cost?

- What’s the MOQ? What if I only need a few thousand to start?

If you’ve asked yourself these questions, you’re not alone. Many U.S. and European brands struggle with turning a creative vision into a successful, manufacturable product.

As a license plate frame OEM based in China, we’ve helped dozens of brands—big and small—launch custom products efficiently. Here’s what you need to know before you get started.

Step 1: Understand the Basics—Materials, Styles, and Manufacturing Options

Before you contact a supplier, it helps to have a rough idea of what you want. The most common custom frame types include:

- Materials: ABS plastic, zinc alloy, stainless steel, aluminum

- Finish options: Chrome plating, matte black paint, brushed metal, full-color printing

- Mounting styles: 2-hole, 4-hole, with or without tabs

- Extras: Custom packaging, logo printing, gift box inserts, screw caps

You don’t need to be an expert—a good OEM partner will help you fill in the blanks—but having reference images or comparable products will speed up the process.

Step 2: What We’ve Learned as an OEM Partner

In our experience, successful custom projects follow a few common patterns:

- Smaller brands often start with 1,000–5,000 pieces—a good OEM should support flexible MOQs.

- Lead time for new tooling is typically 15–20 days, with total production timelines ranging from 30–45 days depending on the design.

- Communication is key—sharing your intended retail price, sales channel (Amazon? In-store?), or packaging ideas helps us recommend the best materials and options.

We’ve worked with Amazon sellers, regional retail chains, and even gift brands launching themed frames (Father’s Day, Christmas, graduation season). Each of these required different priorities—speed, cost control, or high-end finish.

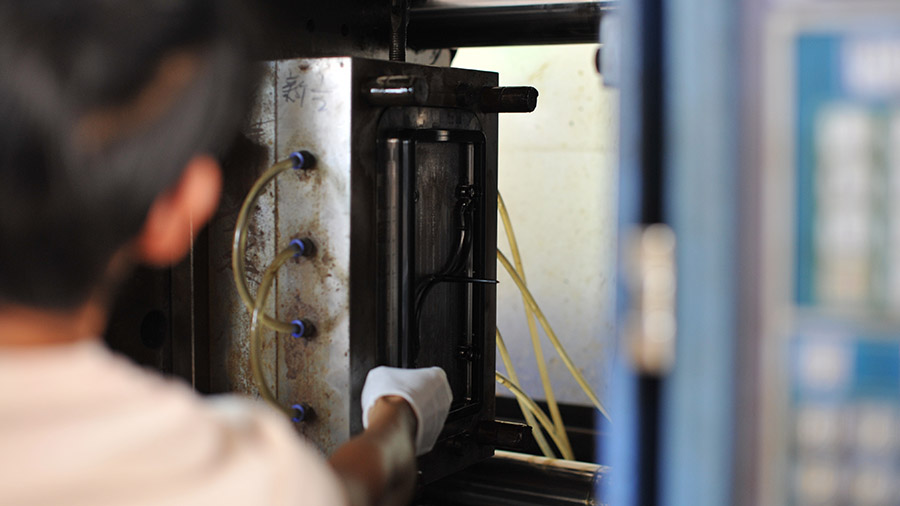

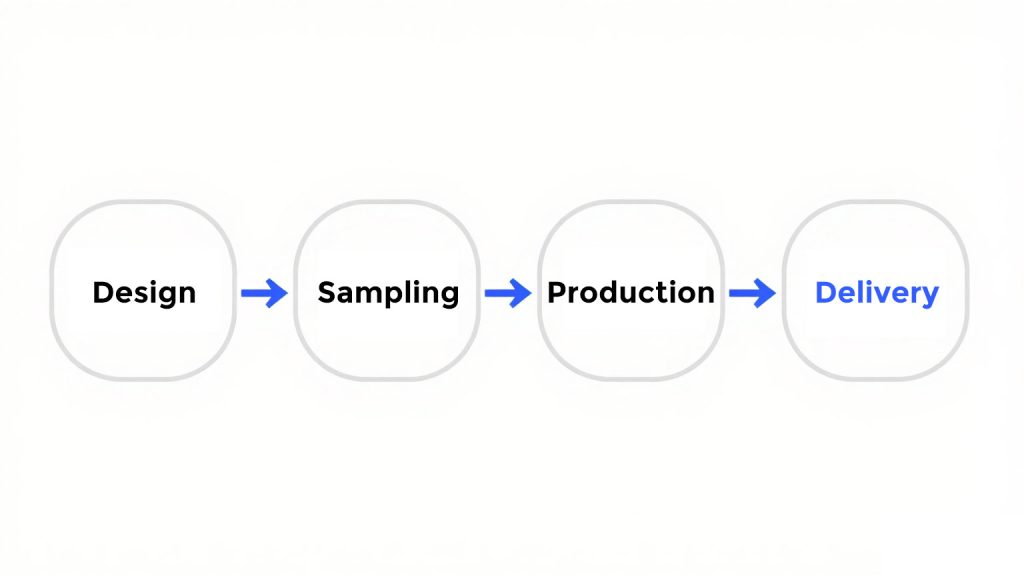

Step 3: How We Support You—From Idea to Delivery

As your manufacturing partner, here’s what we offer to make things easier:

- ✅ Free design consultations: Send us sketches, reference links, or just your concept—we’ll translate that into a workable product spec.

- ✅ Flexible sampling: We can provide photo renderings or physical samples before mass production.

- ✅ Custom molds or shared tooling: Depending on your design, we may recommend open molds (to save cost) or build your exclusive tooling.

- ✅ Full compliance support: Need RoHS, REACH, or Prop 65 compliance? We’ve got the documentation and materials to support your import needs.

- ✅ Fast shipping options: Air, sea, or DDP—we’ll help optimize for your budget and deadline.

Whether you’re launching a branded line or testing the market with your first custom frame, our team is here to simplify the process.

Conclusion: Ready to build your next best-seller?

Developing a custom license plate frame doesn’t have to be overwhelming. With the right OEM partner, you can go from idea to product in weeks—not months—without sacrificing quality or control.

Contact us to start your custom frame project—whether you’re building a retail-ready bestseller or a limited-edition gift frame, we’ll help you make it real with China speed and global standards.

📩 Get a quote today or send us your idea—we’ll respond within 24 hours.