What is Plastic Injection Molding?

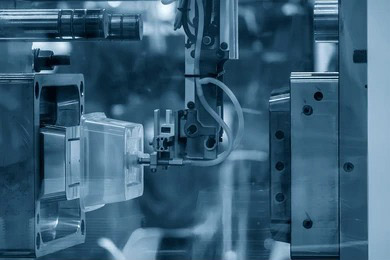

Plastic injection molding is a manufacturing process where molten plastic is injected into a mold under high pressure to create various parts and components. The process starts with plastic pellets, which are heated to a molten state and then forced into a metal mold cavity that mirrors the shape of the desired product. Once the plastic cools and solidifies, the mold is opened, and the finished part is ejected.

Injection molding is widely used for its ability to produce complex shapes with tight tolerances and high repeatability. This is particularly important in industries where consistency and quality are key, such as automotive and consumer products.

Application of Injection Molding Technology in License Plate Frame Manufacturing

In license plate frame manufacturing, injection molding technology plays an essential role in producing precise, durable, and visually appealing products. One of the key advantages of injection molding in this context is the ability to select materials that provide both strength and aesthetics. Common materials used for license plate frames include various types of plastics like ABS (Acrylonitrile Butadiene Styrene) and polycarbonate, which offer durability, weather resistance, and a smooth finish.

The injection molding process allows for mass production of license plate frames with consistent quality. It ensures that each frame maintains the same precise dimensions, making them fit perfectly onto a vehicle, while also being robust enough to withstand the stresses of daily driving, including exposure to different weather conditions and physical impacts.

The versatility of injection molding extends to customization options, including different colors, textures, and finishes, which can enhance the appeal of the frames to meet the needs of consumers, car manufacturers, or businesses looking for branded license plate frames. Whether it’s a sleek, glossy black finish for a luxury vehicle or a matte finish for a more industrial look, injection molding technology allows for high-quality, customized products at scale.

Advantages Brought by Injection Molding Technology

Compared to traditional manufacturing methods, injection molding offers several notable advantages in the production of license plate frames:

- Cost-Effectiveness: Injection molding allows for mass production with minimal labor costs. Once the molds are created, the production of each frame is automated, reducing manual effort and improving overall efficiency. This leads to cost savings that can be passed on to customers.

- Production Efficiency: The speed of the injection molding process allows for the production of large volumes in a relatively short amount of time. The process also has high repeatability, meaning that each batch of frames produced will have the same quality and dimensions as the first, ensuring consistent product quality.

- Precision and Quality Control: Injection molding technology is highly precise, which is essential in ensuring that license plate frames fit vehicles perfectly. This precision also extends to the aesthetic aspects, ensuring the frames have smooth surfaces and sharp details. Additionally, advanced quality control measures can be integrated into the process to identify defects early, ensuring the highest standards of production.

- Durability and Performance: Injection-molded license plate frames are highly durable, with the ability to withstand the rigors of outdoor conditions, including exposure to rain, sun, and varying temperatures. The materials used in injection molding, combined with the precision of the process, ensure that the frames are long-lasting and resistant to wear and tear.

As injection molding technology continues to evolve, we can expect further advancements that will enhance the quality, customization, and sustainability of license plate frames. Some potential developments include:

- Smart Materials: The integration of smart materials that can adapt to environmental conditions or offer additional features like lighting or sensors may open new possibilities for license plate frames. These materials could enhance both functionality and design, making license plate frames more integrated into modern vehicle systems.

- Sustainability: As environmental concerns continue to grow, the use of recyclable or biodegradable materials in injection molding could become more widespread. The development of eco-friendly alternatives that maintain the high standards of durability and performance would benefit both manufacturers and environmentally-conscious consumers.

- 3D Printing Integration: Advances in 3D printing technology could be integrated with traditional injection molding processes. This hybrid approach could further reduce production costs and time while allowing for highly customized, low-volume production of unique license plate frame designs.

- Automation and AI: As automation and artificial intelligence continue to improve, the injection molding process could become even more efficient, with predictive analytics for quality control, faster mold creation, and even more precise customization options.

Injection molding technology has revolutionized the production of license plate frames by offering a highly efficient and cost-effective method for creating durable, high-quality products. With its ability to handle complex shapes, provide customization options, and ensure consistency, injection molding continues to be a cornerstone of modern manufacturing processes.

Looking ahead, innovations in materials, sustainability, and automation will further enhance the capabilities of injection molding, shaping the future of license plate frame manufacturing and beyond. At our factory, we remain committed to leveraging the latest technological advancements to provide our customers with top-tier products that meet the demands of the modern automotive industry.