In the automotive aftermarket, a license plate frame may look simple at first glance, but for brands that want to stand out, every detail counts. Personalized frames—whether for retail, promotional giveaways, or premium collections—require more than just a sketch or logo. To transform a creative concept into a finished product that meets compliance, fits vehicles correctly, and reflects a brand’s quality standards, manufacturers need precise design files.

As a Chinese OEM manufacturer that partners with U.S. and European license plate frame brands, we often see delays and misunderstandings caused by incomplete or incorrect design files. This article explains exactly what types of files your team should prepare, why they matter, and how they speed up the OEM process.

1. Why Design Files Matter in OEM Production

Design files are the bridge between your creative vision and the factory’s engineering reality. For personalized license plate frames, they:

- Define accuracy: Dimensions, proportions, and hole placement must be exact to comply with U.S. or EU regulations.

- Guide manufacturing: Factories need files that are compatible with CAD/CAM systems to design molds, cut materials, and check tolerances.

- Prevent miscommunication: Clear, standardized files reduce guesswork and revisions.

- Save time and cost: The right file format avoids unnecessary conversions and ensures first samples are closer to final approval.

Without the proper files, your project risks rework, delays, and higher costs.

2. The Two Main Categories of Design Files

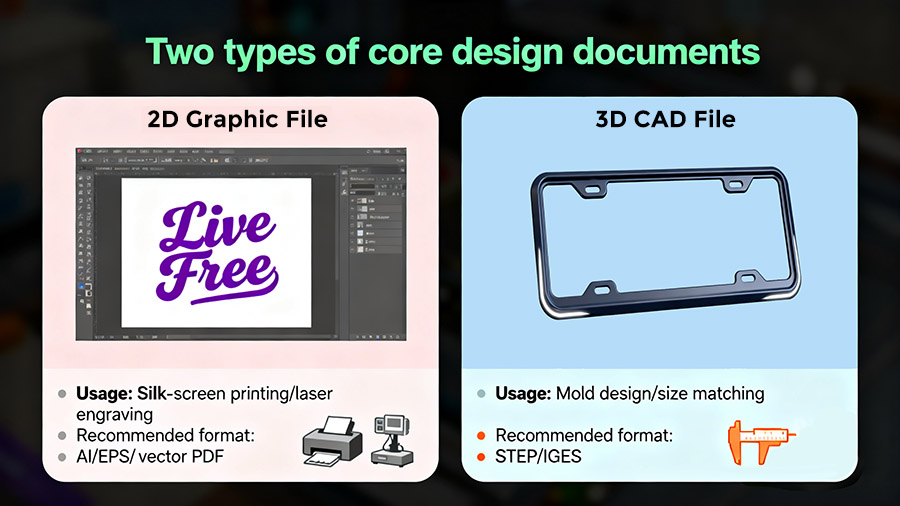

For personalized license plate frames, OEM factories typically request two categories of files:

- 2D Graphic Files – for surface decoration and artwork.

- 3D CAD Files – for structural design and mold engineering.

Both are equally important. A strong logo in vector format helps ensure crisp printing or laser etching, while a detailed STEP file ensures the frame actually fits a standard U.S. or EU plate.

3. 2D Graphic Files: Artwork and Branding Elements

When your project involves logos, slogans, or patterns, the factory will need high-resolution, editable artwork. These files are used for silk-screen printing, UV printing, engraving, or electroplating templates.

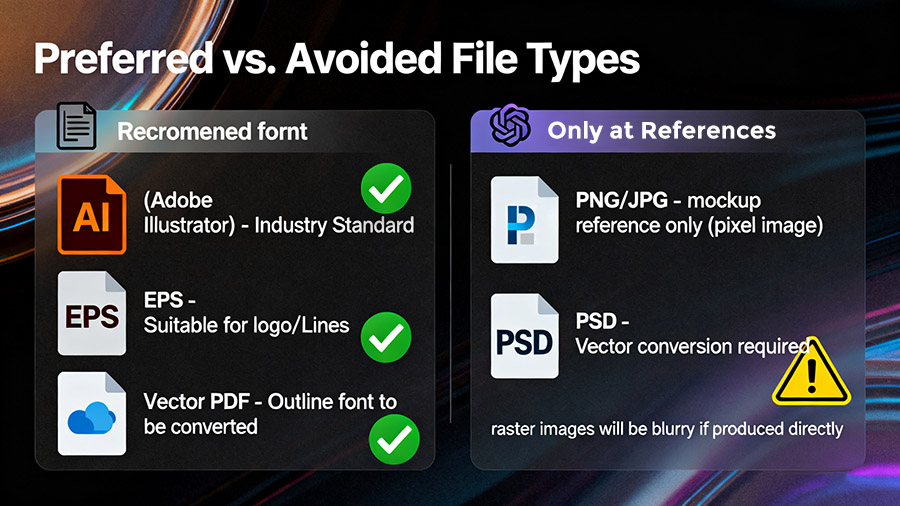

Recommended formats:

- AI (Adobe Illustrator) – the industry standard for vector graphics.

- EPS (Encapsulated PostScript) – another vector format compatible with CAD/CAM.

- PDF (Editable Vector) – acceptable if saved with layers and curves intact.

- PNG or JPG (High Resolution, 300 dpi or above) – acceptable for preview but not ideal for production.

Why vector matters:

Vector files ensure your artwork stays sharp and scalable. A blurry logo in JPG format might look fine on a computer screen, but once enlarged for laser engraving on stainless steel, the flaws become obvious.

4. 3D CAD Files: The Backbone of Manufacturing

Unlike flat items such as decals or stickers, license plate frames are three-dimensional products. They must be molded, cast, or machined to exact specifications. That’s why OEM factories require 3D CAD files—without them, it’s almost impossible to move forward efficiently.

Common 3D file formats requested by OEMs:

- STEP (.step / .stp) – the most widely accepted neutral CAD format.

- IGES (.igs / .iges) – often used in legacy systems, still acceptable.

- SolidWorks (.sldprt, .sldasm) – useful if your design team works in SolidWorks.

- 3D PDF – good for sharing visuals with non-technical stakeholders, though less useful for tooling.

Why 3D files are critical:

- Mold design: The factory’s engineers need to build steel molds based on precise geometry.

- Fit testing: Frames must match vehicle license plate sizes (e.g., 6” x 12” for the U.S., 520 mm x 110 mm for EU).

- Tolerance analysis: Ensures no interference with screws, bumpers, or plate visibility.

- Surface detail: Helps identify curved edges, embossed letters, or recessed areas for decoration.

Providing a STEP or IGES file can shorten tooling lead time by several weeks, since the OEM doesn’t have to re-create your concept from scratch.

5. Technical Specifications Beyond File Format

Beyond 2D and 3D files, your design package should include key technical notes:

- Dimensions – exact measurements with tolerances (e.g., ±0.1 mm).

- Mounting hole positions – aligned with U.S. 2-hole or 4-hole standards, or EU norms.

- Material specification – ABS plastic, stainless steel, aluminum, or zinc alloy.

- Surface finish – polished, brushed, matte, painted, or chrome-plated.

- Color details – Pantone codes for brand consistency.

- Special requirements – anti-UV coating, anti-rust treatment, or packaging details.

This combination of visual files + engineering notes ensures nothing gets lost between design and production.

6. File Transfer Best Practices

Even the right files can cause issues if not shared properly. Consider these best practices:

- Use cloud storage: Share via Google Drive, Dropbox, or OneDrive rather than email attachments (large files often get corrupted).

- Check version control: Make sure the factory is using your latest approved file, not an outdated draft.

- Compress with care: ZIP files are fine, but avoid overly aggressive compression that can corrupt data.

- Provide a preview image: A simple PDF or JPG of the final design helps confirm alignment after the factory imports your CAD file.

7. Common Pitfalls to Avoid

Based on our OEM experience, these are the top mistakes that slow down projects:

- Sending only a JPG logo – factories cannot build tooling from raster images.

- Forgetting 3D files – delays mold design and sample creation.

- Unclear hole spacing – different markets (U.S. vs EU) require different mounting standards.

- No Pantone references – colors may shift between monitors and printers.

- Last-minute changes – even small edits to 3D files can mean re-cutting a mold.

Avoiding these pitfalls can save weeks of unnecessary back-and-forth.

8. How the Right Files Accelerate Your OEM Project

When your design team delivers both 2D artwork files and 3D engineering files with clear specifications, the benefits are immediate:

- Faster sampling – the factory can jump straight into prototyping.

- Lower costs – fewer revisions and less wasted tooling effort.

- Higher accuracy – samples align more closely with your expectations.

- Stronger partnership – your OEM partner sees you as professional and easy to collaborate with.

In today’s competitive market, speed-to-launch is often a brand’s biggest advantage. Proper file preparation is a simple way to gain that edge.

Conclusion

Design files are more than a formality—they are the foundation of successful OEM collaboration. For personalized license plate frames, your team should prepare:

- 2D vector artwork files (AI, EPS, PDF) for logos and decoration.

- 3D CAD files (STEP, IGES, SolidWorks) for structure and tooling.

- Clear technical notes on dimensions, materials, colors, and finishes.

By delivering this complete package, you help your OEM partner in China move quickly, reduce risks, and deliver a frame that matches your brand’s vision with precision.