In the fiercely competitive U.S. license plate frame market, launching a new design can feel like placing a high-stakes bet. According to industry data, a standard metal frame mold typically costs around $5,000. Yet for small to mid-sized brands, the failure rate of new product launches exceeds 40%, making each mold investment a potential sunk cost.

Have you ever held back on a holiday limited edition due to a 1,000-piece minimum mold requirement? Or paid $2,000 every time you tweak the design—only to find prototyping costs surpass your product margins?

The good news: Chinese factories are now offering a flexible, low-cost prototyping strategy that cuts sampling expenses by over 70%. With a modest budget, you can test new ideas and seize market opportunities—without going all-in on tooling.

Technical Breakdown: Low-Cost Prototyping Methods by Process

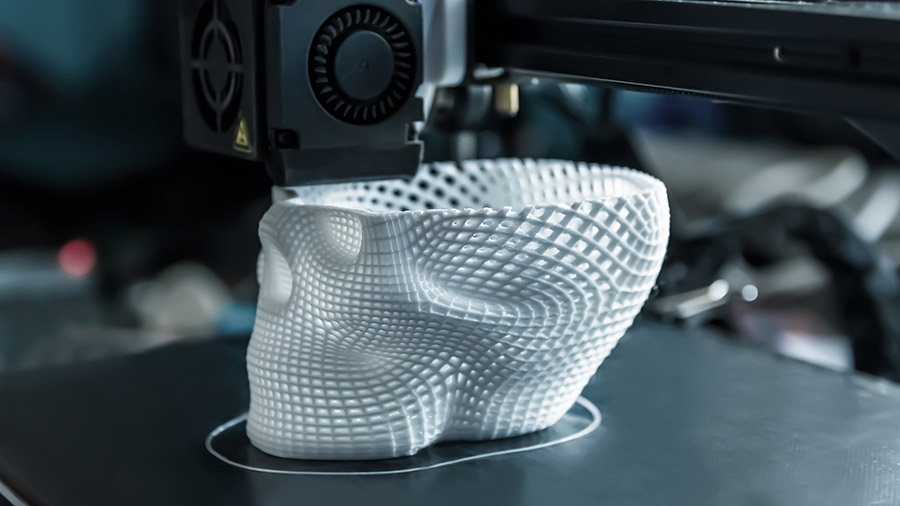

1. 3D Printing: The Most Cost-Effective Tool for Rapid Iteration

3D printing has become the go-to method for short-run prototyping. In one case, a U.S. customer approached us with a metal license plate frame design that required a powder-coated finish in gloss and matte variations. Instead of committing to full-scale molds, we recommended using aluminum alloy 3D printing to simulate the final look and feel.

For just $300, we produced four high-fidelity samples. Dimensional accuracy was excellent: a 7.88mm design element printed with tolerances between 7.82–7.93mm, meeting customer requirements. The client quickly finalized the design based on these samples and moved into production.

For plastic versions, PLA 3D printing brings even more savings—about $200 for 10 samples, without any mold costs. One U.S. brand had us 3D print a license plate frame with an embossed logo and received working samples in just 24 hours. By refining the mold design based on the print, they avoided two costly mold revisions and saved over $6,000.

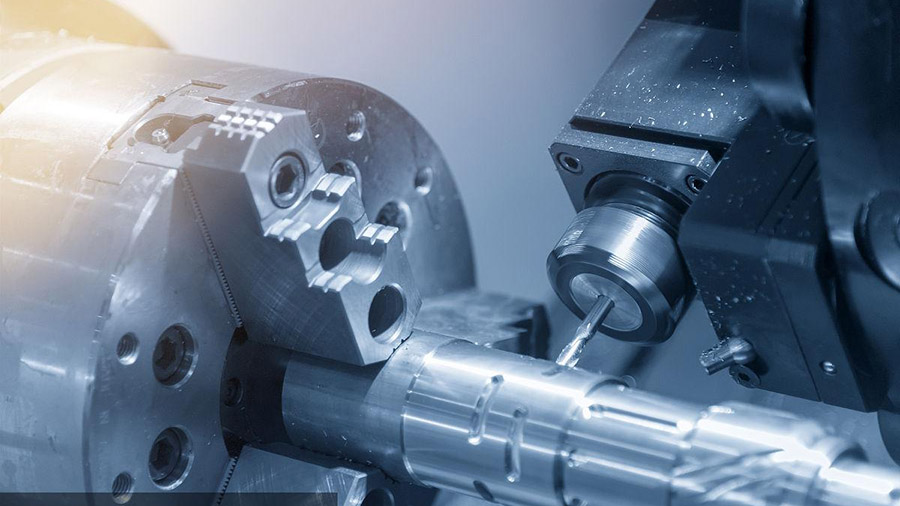

2. CNC Machining: Precision Sampling for Metal Designs

For aluminum or stainless steel license plate frames, CNC machining is ideal when strength and precision matter. Priced at $50–100 per hour, this method offers unmatched control for structural testing.

Case Study: Structural Validation of a Stainless Steel Frame

A client needed to validate the strength of a stainless steel frame with a complex design. Using CNC machining, we produced the sample within 7 days at a cost of $500.

- Frame wall thickness (1.5mm spec): Actual range 1.48–1.52mm, deviation ≤ 0.02mm

- Hollowed-out logo radius (R1.5mm): Measured R1.48–1.53mm, outperforming ±0.1mm typical in stamping

- Under 10kg deformation testing, strength deviation from mass production was under 5%

Compared to stamping (which requires $3,000–$5,000 molds and 15–20 days lead time), CNC cuts both cost and time—no mold fees, no trial-and-error revisions.

3. Manual Assembly + Simple Fixtures: Budget Option for Aesthetic Review

For basic visual validation, combining laser-cut acrylic bases with hand-bent metal strips offers the cheapest approach. These mock-ups cost as little as $15 per unit and are easy to fabricate.

While precision and repeatability are limited, this method is perfect for early-stage feedback or minimal design testing.

4. Silicone Molding: A Flexible Option for Soft Parts and Small Runs

Silicone molding is ideal for soft materials like silicone frames or bumper guards. It takes 5–7 days and costs around $500–800, making it a smart option for pilot runs under 500 units.

At a Glance: Cost, Lead Time & Best Use Cases

| Process | Sample Cost (10 pcs) | Lead Time | Best Use Case | Mass Production Transition |

| 3D Printing (PLA) | $200–$500 | 1–3 days | Plastic samples, complex design iteration | Mold refinement needed |

| CNC (Aluminum/Steel) | $500–$1500 | 3–7 days | Metal frames, strength/precision verification | Direct mold-free production possible |

| Manual + Fixtures | $150–$300 | 5–10 days | Simple visual mockups | Requires new mold for production |

| Silicone Molding | $500–$800 | 5–7 days | Small-batch soft parts (e.g., silicone edges) | Best for low-volume orders |

Value Beyond Samples: From Prototypes to Full Production

Sampling is more than a test—it’s a bridge to mass production. That’s why we don’t just deliver prototypes—we help optimize for manufacturability. Our engineering team offers insights on:

- Wall thickness and support structure for 3D prints

- Tolerance control in CNC parts

- Cost forecasting for production materials

We also support trial production from just 10 units, using the same process as sampling. This allows brands to validate market response with minimal inventory risk. One of our U.S. clients launched five new SKUs in three months, boosting their hit rate from 35% to 60%, with the first 1,000-piece trial selling out at 150% of expected sales.

End-to-End Support: From 10 Samples to 100,000 Units

Whether you’re prototyping a new concept or scaling up a proven design, our supply chain can handle it. We manage flexible production volumes, and our team is experienced in global shipping—ensuring fast delivery and smooth customs clearance.

Ready to Test Your Design?

Submit the form below to receive our License Plate Frame Sampling Cost Calculator, featuring real-world quote templates for 3D printing, CNC, and more.

👉 First-time clients get a satisfaction guarantee—if you’re not happy with your prototype, we’ll refund your sampling fee. Even better, approved sample costs can be credited toward future production orders.

Accurate prototyping is the first step to product success.

Click below to start your low-risk, high-reward sampling journey.