For boutique license plate frame brands or gift companies in the U.S. and Europe, working with an OEM manufacturer in China offers massive cost advantages—but also brings new variables to navigate. Understanding MOQ (Minimum Order Quantity), tooling, and lead times is key to making confident and profitable sourcing decisions.

This article breaks down the three most critical manufacturing terms and offers actionable advice from a Chinese supplier’s perspective.

1. What Is MOQ and Why Does It Matter?

MOQ stands for Minimum Order Quantity, and it’s the minimum number of units a factory is willing to produce for a custom project.

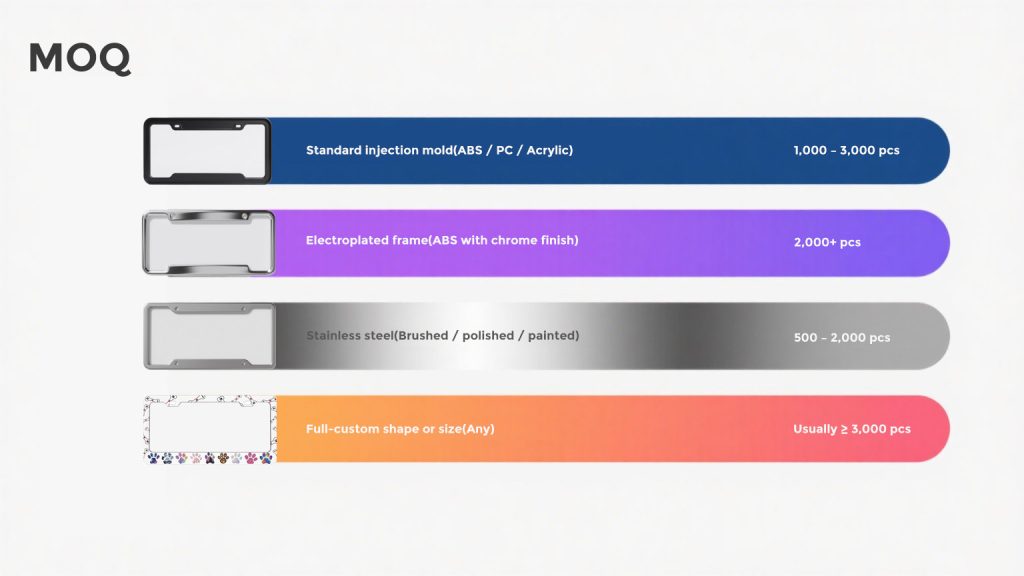

✅ Common MOQ Scenarios for License Plate Frames:

| Process Type | Material/Finish | Common MOQ |

|---|---|---|

| Standard injection mold | ABS / PC / Acrylic | 1,000 – 3,000 pcs |

| Electroplated frame | ABS with chrome finish | 2,000+ pcs |

| Stainless steel | Brushed / polished / painted | 500 – 2,000 pcs |

| Full-custom shape or size | Any | Usually ≥ 3,000 pcs |

💡 Tip for small brands: Ask if your supplier offers shared mold options or semi-custom solutions. These can reduce MOQ and upfront costs significantly.

2. Tooling Costs: One-Time or Ongoing?

Tooling refers to the mold or die required to manufacture your license plate frame design. For injection-molded plastic or die-cast metal frames, tooling is essential.

🎯 What You Need to Know:

- Custom mold costs range from $800 to $3,000+ depending on complexity and size.

- Tooling is usually a one-time investment for long-term production use.

- Some manufacturers retain the mold ownership, while others allow you to own it.

💡 Tip: Always clarify who owns the mold after payment, whether revisions are included, and the expected mold life (e.g., how many cycles before replacement is needed).

3. Lead Times: From Sampling to Bulk Production

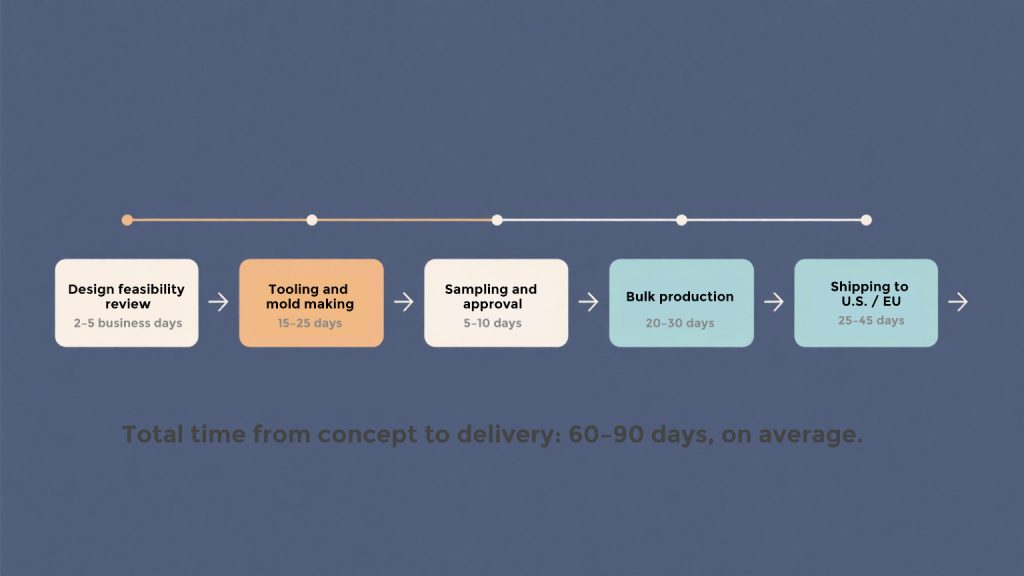

Time planning is often underestimated. Here’s a general timeline for OEM license plate frame orders:

| Stage | Time Needed |

|---|---|

| Design feasibility review | 2–5 business days |

| Tooling and mold making | 15–25 days |

| Sampling and approval | 5–10 days |

| Bulk production | 20–30 days |

| Shipping to U.S. / EU | 25–45 days (depending on method) |

🔍 Total time from concept to delivery: 60–90 days, on average.

💡 Tip: Always build in buffer time if you’re preparing for a holiday launch, trade show, or Amazon release.

4. How We Help Small Brands Navigate These Issues

As an OEM partner focused on license plate frames, we regularly work with small to mid-sized brands and distributors. Here’s how we support them:

- ✅ Feasibility review before tooling to reduce risk

- ✅ MOQ flexibility for repeat buyers or shared projects

- ✅ Clear mold agreements (ownership, maintenance, lifespan)

- ✅ Status updates at every milestone (tooling, sample, production)

Final Thoughts: Don’t Let Jargon Hold You Back

Sourcing from China doesn’t have to be overwhelming. Understanding just three core terms—MOQ, tooling, and lead time—can save your project from delays, waste, or hidden costs. Whether you’re a startup launching your first license plate frame or an established brand looking for a new supplier, it all starts with clear communication.

📩 Have a design in mind or want to check MOQ for your next frame project? Contact us to get a free feasibility assessment from our team in China.